The world is changing rapidly, and the workplace will be transformed in basic ways because of scientific advances. The future will become more technological and automated, so it’s crazy for America to continue admitting millions of low-skilled immigrants when increasingly jobs require tech-educated people, not illiterate agricultural workers from Guatemala.

Washington should wake up and realize that

Automation makes immigration obsolete.

The Times article explains clearly what the employment outcome for human workers will be because of the increasing abilities of robots.

]]>A Warehouse Robot Learns to Sort Out the Tricky Stuff, New York Times, January 29, 2020

LUDWIGSFELDE, Germany — Inside a warehouse on the outskirts of Berlin, a long line of blue crates moved down a conveyor belt, carrying light switches, sockets and other electrical parts. As they came to a stop, five workers picked through the small items, placing each one in a cardboard box.

At Obeta, an electrical parts company that opened in 1901, it is the kind of monotonous task workers have performed for years.

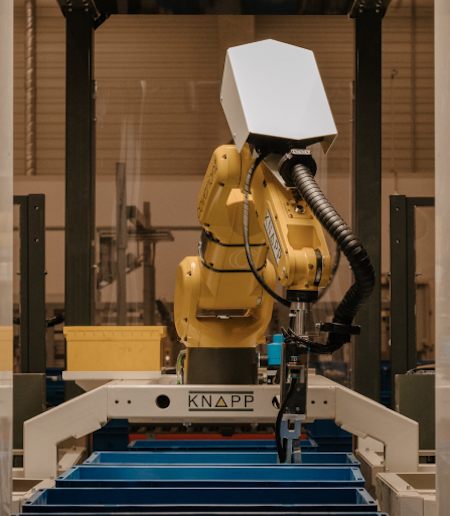

But several months ago, a new worker joined the team. Stationed behind protective glass, a robot using three suction cups at the end of its long arm does the same job, sifting through parts with surprising speed and accuracy.

While it may not seem like much, this component-sorting robot is a major advance in artificial intelligence and the ability of machines to perform human labor.

As millions of products move through warehouses run by Amazon, Walmart and other retailers, low-wage workers must comb through bin after bin of random stuff — from clothes and shoes to electronic equipment — so that each item can be packaged and sent on its way. Machines had not really been up to the task, until now.

“I’ve worked in the logistics industry for more than 16 years and I’ve never seen anything like this,” said Peter Puchwein, vice president of Knapp, an Austrian company that provides automation technology for warehouses.

Standing nearby at the Obeta warehouse, the California engineers who made the robot snapped pictures with their smartphones. They spent more than two years designing the system at a start-up called Covariant.AI, building on their research at the University of California, Berkeley.

Their technology is an indication that, in the coming years, few warehouse tasks will be too small or complex for a robot. And as the machines master tasks traditionally handled by humans, their development raises new concerns about warehouse workers losing their jobs to automation.

Because the online retail business is growing so quickly — and most companies will be slow to adopt the latest robotic technologies — economists believe the advances will not cut into the overall number of logistics jobs anytime soon. But the engineers building these technologies admit that at some point most warehouse tasks will be done by machines. Human workers will need to find other things to do. (Continues)

Jeff Bezos [...]]]>

Jeff Bezos — who became a billionaire by skillfully adding robots to his online Amazon store — opined at re:MARS that advanced robotic hands will be achieved in a decade. That techno advance would be a serious game-changer as far as replacing humans in the workplace, because manual dexterity has been much harder to create than basic functional intelligence of the sort that is often used in business machines now.

For example, Amazon warehouses are run by a big computer brain that keeps track of stock, individual orders and where items are located on various racks of merchandise. But the little orange robots deliver the customer orders to workers to pack them up for shipment. When robot hands reach human-like dexterity, then Bezos can get his desired totally automated warehouses.

Below, Amazon’s Kiva warehouse robots are wired in to a computer system that tracks customer orders as well as where everything is located on the floor.

The basic Kiva warehouse robot will be getting an assist from a new smart machine called Pegasus that moves individual parcels from packers to sorting chutes. Note how the robot is characterized as a helper to workers rather than a future replacement for them in the company video below:

Finally, here’s a report about Bezos’ plan for dexterous robot hands to come in the automated future:

]]>Amazon’s Bezos says robotic hands will be ready for commercial use in next 10 years, Reuters, June 6, 2019

LAS VEGAS (Reuters) – Amazon.com Inc Chief Executive Jeff Bezos said on Thursday he expects there will be commercial robots in the next 10 years that can grasp items as reliably as humans, a development that could lead to the automation of warehouse jobs around the world.

The remark, made on stage at Amazon’s “re:MARS” conference in Las Vegas, underscored how companies and university researchers are rapidly developing technology to perform human tasks, whether for elder care in the home or for the picking and stowing of goods in retail warehouses.

“I think grasping is going to be a solved problem in the next 10 years,” he said. “It’s turned out to be an incredibly difficult problem, probably in part because we’re starting to solve it with machine vision, so (that means) machine vision did have to come first.”

Bezos did not discuss any Amazon deployments of the technology, which it has tested from the Boston-area startup Soft Robotics, for instance, a person familiar with the matter told Reuters previously here

The company has said it views automation as a way to help workers.

Still, Amazon is known for its drive to mechanize as many parts of its business as possible, whether pricing goods or transporting items in its warehouses. It employs hundreds of thousands of people, many of whose primary task is grasping, scanning and placing customer orders.

A variety of companies other than Amazon have also rolled out robotic hands for limited warehouse pilots. (Continues)

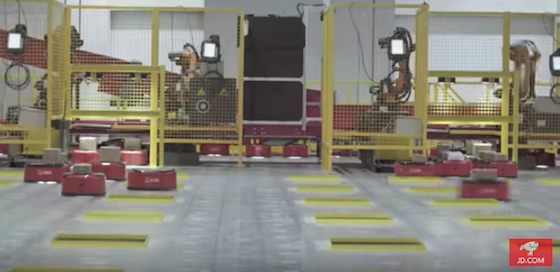

The warehouse robots of JD.com in Red China look similar to Amazon machines.

Warehouse jobs used to be a possibility for low-skilled persons, but that occupation is one of many that are being disappeared by automation. That trend bodes poorly for the future of human employment.

And given that most immigrants and aliens coming to the US are low-skilled, we shouldn’t continue to admit them like they’re going to be employable in a decade or so. They won’t.

Oxford researchers forecast in 2013 that nearly half of American jobs were vulnerable to machine or software replacement within 20 years. Rice University computer scientist Moshe Vardi believes that in 30 years humans will become largely obsolete, and world joblessness will reach 50 percent. The Gartner tech advising company believes that one-third of jobs will be done by machines by 2025. The consultancy firm PwC published a report last year that forecast robots could take 38 percent of US jobs by 2030. Last November the McKinsey Global Institute reported that automation “could displace up to 800 million workers — 30 percent of the global workforce — by 2030.” Forrester Research estimates that robots and artificial intelligence could eliminate nearly 25 million jobs in the United States over the next decade, but it should create nearly 15 million positions, resulting in a loss of 10 million US jobs.

But wait, is “humanless” really a word now that the age of robots is upon us?

]]>The world’s first humanless warehouse is run only by robots and is a model for the future, CNBC, October 30, 2018

• Mujin, a start-up spun out of Tokyo University, has developed robot controllers that can fully automate warehouses and fulfillment centers.

• Its customer, JD.com, has what it calls the world’s first fully automated e-commerce warehouse in China equipped with Mujin robots.

• The Japanese start-up wants to help automate warehouses in the United States.At a recent technology show in Tokyo, a large robot arm reached into a full-sized mockup of a shipping container and began unloading boxes from it. Set on a platform that moved back and forth, the robot was doing a job usually carried out by warehouse workers and forklift operators. The goal of the company that’s developing it, Mujin, is total automation.

The system, still a prototype, doesn’t work perfectly — it accidentally damaged a box during the demo — but it’s going to be trialed in warehouses in Japan this year.

“Lifting heavy boxes is probably the most backbreaking task in warehouse logistics,” said Mujin’s American co-founder and CTO, Rosen Diankov. “A lot of companies are looking for truck unloading systems, and I believe we’re the closest to commercialization.”

The Tokyo-based start-up is aiming to be a leader in automating logistics processes. To do that, it’s building robot controllers and camera systems and integrating them with existing industrial robot arms. The key product here is the controllers — each about the size of a briefcase, one for motion planning and one for vision — that act as an operating system that can control the hardware from any robot manufacturer. If a goal such as grasping an object is input, the controllers automatically can generate motions for robots, eliminating the traditional need to “teach” robots manually. The result, according to the company, is higher productivity for users.

Simply put, the technology — based on motion planning and computer vision — makes industrial robots capable of autonomous and intelligent action.

Mujin turned heads when it showed off its transformation of a warehouse operated by Chinese e-commerce giant JD.com. The 40,000-sq-m facility in Shanghai began full operations in June. It was equipped with 20 industrial robots that pick, transfer and pack packages using crates on conveyor belts, as well as camera systems and Mujin robot controllers. Other robots carted merchandise around to loading docks and trucks.

Will robots take our jobs? from CNBC.

(Continues)

As part of Wal-mart’s competition with Amazon, the store chain is utilizing Amazon’s technology strategy by moving forward with automation to up its e-commerce game.

Naturally, the efficiency and cost-savings [...]]]>

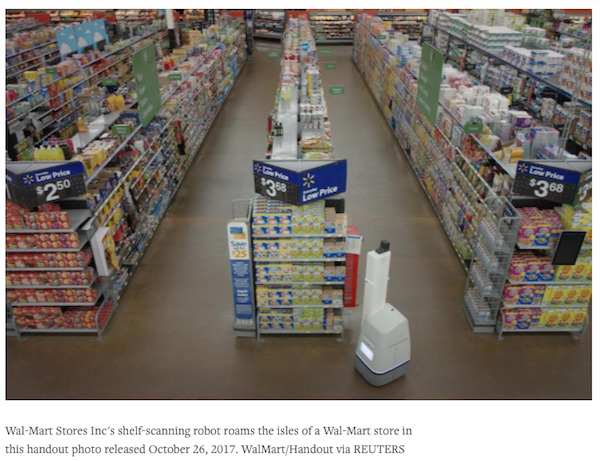

As part of Wal-mart’s competition with Amazon, the store chain is utilizing Amazon’s technology strategy by moving forward with automation to up its e-commerce game.

Naturally, the efficiency and cost-savings are emphasized, rather than the inevitable job loss.

Wal-Mart’s new robots scan shelves to restock items faster, Reuters, October 26, 2017

CHICAGO (Reuters) – Wal-Mart Stores Inc is rolling out shelf-scanning robots in more than 50 U.S. stores to replenish inventory faster and save employees time when products run out.

. . . “If you are running up and down the aisle and you want to decide if we are out of Cheerios or not, a human doesn’t do that job very well, and they don’t like it,” Jeremy King, chief technology officer for Walmart U.S. and e-commerce, told Reuters.

The company said the robots would not replace workers or affect employee headcount in stores.

The robots are 50 percent more productive than their human counterparts and can scan shelves significantly more accurately and three times faster, King said. Store employees only have time to scan shelves about twice a week.

The idea of installing robots to automate retail is not new. Rival Amazon.com Inc uses small Kiva robots in its warehouses to handle picking and packing, saving almost 20 percent in operating expenses. . .

Even more futuristic are the drone robots that fly around warehouses to do inventory, as the BBC recently reported:

The flying drones that can scan packages night and day, October 27, 2017

Flying drones and robots now patrol distribution warehouses – they’ve become workhorses of the e-commerce era online that retailers can’t do without. It is driving down costs but it is also putting people out of work: what price progress? . . .

What price progress indeed? A viable economy requires shoppers as well as products, but nobody in government seems concerned about the shrinkage of the demand side of the equation. Wouldn’t preparing for the automated future make more sense than pretending it isn’t coming?

Certainly America shouldn’t import more immigrant workers, since they won’t be needed. The remaining jobs should go to Americans, period, because:

Automation makes immigration obsolete.

Need convincing? Experts paint a grim picture:

Oxford researchers forecast in 2013 that nearly half of American jobs were vulnerable to machine or software replacement within 20 years. Rice University computer scientist Moshe Vardi believes that in 30 years humans will become largely obsolete, and world joblessness will reach 50 percent. The Gartner tech advising company believes that one-third of jobs will be done by machines by 2025. The consultancy firm PwC published a report earlier this year that forecast robots could take 38 percent of US jobs by 2030.

]]>Amazon warehouses depend on [...]]]>

Amazon warehouses depend on the little orange robots to bring racks of merchandise to human pickers who pack the boxes with the customers’ orders.

The contest used to be called the Amazon Picking Challenge, but the big management brains may have thought it was time for a classier name. I see the earlier Url for the event, AmazonPickingChallenge.org has been transformed into AmazonRobotics.com.

“Picking” is the term for pulling items from the warehouse inventory to be packed into boxes for customers’ orders. But as the video below shows, packing may be the harder challenge. The robot sucks up objects well enough and then drops them into a large box, with no attempt to use space efficiently. Amazon may have to order a lot of extra large boxes if this sort of machine is adopted.

I’ve blogged about this competition over the last three years and can report no stunning breakthroughs. For example, the robots in the video following aren’t able to pick up the objects on every try:

Below is the winner, from Australia, Robot Vision’s Cartman, that does the basic grab-and-drop pretty well, but no human pickers need to be worried about their jobs just yet.

The upshot is the amazing dexterity of the human hand coupled with our brains is very hard to recreate in a machine. However, the machines are going gangbusters in many other areas of work, from farms to factories, so the fact remains that America should seriously reduce the number of immigrant workers imported by the government. We have plenty of them already.

]]>Amazon’s New Robo-Picker Champion Is Proudly Inhuman, MIT Technology Review, July 31, 2017

It only needs to see seven images of a new object before it can reliably spot and grab it.

A robot that owes rather a lot to an annoying arcade game has captured victory in Amazon’s annual Robotics Challenge.

E-commerce companies like Amazon and Ocado, the world’s largest online-only grocery retailer, currently boast some of the most heavily automated warehouses in the world. But items for customers’ orders aren’t picked by robots, because machines cannot yet reliably grasp a wide range of different objects.

That’s why Amazon gathers together researchers each year to test out machines that pick and stow objects. It’s a tough job, but one that could ultimately help the company to fully automate its warehouses. This year the task was made even harder than usual: teams had only 30 minutes for their robots to familiarize themselves with the objects before trying to pick them out of a jumble of items. That, says Amazon, is supposed to better simulate warehouse conditions, where new stock is arriving all the time and pallets may not be neatly organized.

The winner, a robot called Cartman, was built by the Australian Centre for Robotic Vision. Unlike many competitors, which used robot arms to carry out the tasks, Cartman is distinctly inhuman, with its grippers moving in 3-D along straight lines like an arcade claw crane. But it works far, far better. According to Anton Milan, one of Cartman’s creators, the device’s computer-vision systems were crucial to the victory. “One feature of our system was that it worked off a very small amount of hand annotated training data,” he explained to TechAU. “We only needed just seven images of each unseen item for us to be able to detect them.”

That kind of fast learning is a huge area of research for machine learning experts. Last year, DeepMind showed off a so-called “one-shot” learning system, that can identify objects in a image after having only seen them once before. But the need to identify objects that are obscured by other items and pick them up means that Cartman needs a little more data than that.

(Read more: TechAU, “Robot, Get the Fork Out of My Sink,” “Machines Can Now Recognize Something After Seeing It Once,” “Inside Amazon”)

Below, Kiva robots operate from a computer system that tracks and moves everything in the warehouse. The robots scoot under mobile racks of merchandise and move needed items to human-run packing stations for shipment.

But technology designers have been catching up with different sorts of robots that do the same work as the Kiva models.

The loss to society is a large sector of jobs in retail, and they are disappearing from the semi-public space of stores to private areas of warehouses where we don’t see humans replaced by machines. The “death of retail” is now a grim topic on the financial pages, as major retail companies are closing some or all of their stores. In January, Time reported “Department Stores Are in a Death Spiral” with the example that Macys planned to close 100 stores with the loss of 10,000 jobs. Other big-name retailers are cutting back severely as well. The story notes that as online outlets improve shipping time, shoppers increasingly use brick and mortar stores less.

The long-term outlook for jobs is dismal throughout the economy because of smart machines, yet Washington continues to import human workers as if there will be a need for them in the automated future, which there won’t. Oxford researchers forecast in 2013 that nearly half of American jobs were vulnerable to machine or software replacement within 20 years. Rice University computer scientist Moshe Vardi believes that in 30 years humans will become largely obsolete, and world joblessness will reach 50 percent. The Gartner tech advising company believes that one-third of jobs will be done by machines by 2025. Forrester Research Inc. has a more optimistic view, that there will be a net job loss of 7 percent by 2025 from automation. The recent PwC forecast was only slightly less severe than the Oxford numbers. So every automation expert thinks the technology will decrease jobs which is why business is investing big money to switch away from wage earners.

It remains to be seen how many jobs President Trump can raise in America: there is certainly repressed business energy to be tapped after eight years of Obama policies. But long term, many human jobs are being replaced by machines, and we should act accordingly. Step one should be slashing immigration because America won’t need a million new workers per year.

Automation makes immigration obsolete.

Washington needs to wake up to the technological future. It will be very different.

]]>Amazon’s Robot War Is Spreading, Bloomberg, April 5, 2017

A slew of new automation specialists appear on the warehouse battlefield.It was Amazon that drove America’s warehouse operators into the robot business.

Quiet Logistics, which ships apparel out of its Devens, Mass., warehouse, had been using robots made by a company called Kiva Systems. When Amazon bought Kiva in 2012, Quiet hired scientists. In 2015 it spun out a new company called Locus Robotics, which raised $8 million in venture capital. Last year, Locus unveiled its own warehouse robotics solution called the LocusBot—first using it for its own business, then selling them to companies that ship everything from housewares to auto parts.

Now, Locus has landed a bigger fish: It’s selling its robots to DHL Supply Chain (a unit of Deutsche Post DHL Group), the world’s largest third-party logistics company. DHL will use the machines at a Memphis, Tenn., location to help ship surgical devices to operating rooms across the country.

To do that, Locus’s software directs a LocusBot to a shelf where the specific item is located. A human worker meets it there, reads a description of the item off an iPad, and drops it into a plastic bucket mounted on the machine. The idea is that the robot does the majority of the traveling, while the worker simply patrols a specified zone.

“The first trend was to try to replace humans,” said Rick Faulk, chief executive of Locus. “Now it’s about humans and robots working collaboratively.” The sticker price on a LocusBot is $35,000.

Locus isn’t alone. Amazon’s acquisition of Kiva set off an arms race among robot makers and shippers across the U.S. who scurried to keep up with the e-commerce giant. That includes 6 River Systems, a Waltham, Mass.-based company founded by former Kiva employees, which this week is showing its robot at ProMat, an industry trade show in Chicago. There’s also Fetch, a company in San Jose, Calif., whose robot scuttles around warehouses and also does the walking for workers.

The big changes in warehouse robotics, said Adrian Kumar, vice president for solutions design at DHL, come in response to the rise of e-commerce. For decades, operators were focused on the task of loading pallets and shipping them to retailers, who broke up the shipments and routed them to retail locations. Fulfilling online orders, on the other hand, requires shippers to pack boxes with a diverse set of individual items and route them on to customers’ homes.

At the Quiet Logistics warehouse, the robots shorten the distance a warehouse worker travels on a typical day from 14 miles to less than 5 miles, Faulk said. The robots, meanwhile, park themselves directly in front of the shelf that the worker is supposed to pick from, decreasing the risk the human will pick the wrong item. That makes the job easier, and is appealing to employees. “Working with robots is a fun thing to do,” Faulk said.

What that means for warehouse humans is an open question. There were 939,000 people working in the industry in February, up 44 percent over the past 10 years, according to data from the U.S. Bureau of Labor Statistics. The rise of e-commerce has created a need for more hands to pick items and pack boxes. Seattle-based Amazon.com Inc.’s rapid shipping times have taught customers to expect goods on their doorstep in two days or less, fueling a warehouse boom as retailers scramble to amass distribution hubs closer to their shoppers.

Logistics firms can have a hard time hiring enough people, particularly during peak shopping seasons. Adding robots should ease some of the seasonal shortages, and may make the work less physically demanding. Working conditions at U.S. warehouses are often scrutinized for their grueling nature: Pickers complain of exhausting shifts, sometimes in oppressive heat or biting cold. Many of the jobs are temporary, fluctuating with the shopping calendar.

Across the economy, almost 25 million jobs will be lost to automation in the next 10 years, while the new technology will create 15 million jobs, according to research firm Forrester. In the logistics business, smarter warehouse bots will likely reduce the number of people it takes to run a fulfillment center.

“I don’t think people are investing in automation because of a near-term labor shortage,” said Karl Siebrecht, CEO at Flexe, a Seattle-based company that bills itself as the Airbnb of warehouse space. “It’s about improving productivity. Fundamentally, that means people will be replaced.”